Description

Polypropylene BOPP.

The bioriented polypropylene – coextruded biaxially oriented polypropylene films are focused on two directions. They are issued in the form of a cloth/linen with the thickness from 20 up to 40 µm. They are chemically neutral, nontoxic, overprinting is possible. Films from biaxially oriented polypropylene are used for packing various foodstuffs, bread and confectionery, flowers, cigarettes, perfumery, loose products and other kinds of products.

BOPP films possess the following properties:

- Increase of barrier properties;

- Strengthening;

- Rigidity;

- Optical properties;

- Increase of weldability;

- Decrease of water- and gas permeabilities;

- Increase of adhesive properties;

- Ability to metallization.

BOPP films maintain high mechanical properties up to-50C, allowing the storage of the packed products in conditions of deep frost. The permeability of BOPP films to water vapours is 3 times lower than that of polyethylene, 5 times lower than that of PET, and 6 times lower than that of PVC. This fact makes them a valuable material for packing of all products which are sensitive to moisture (cold cereals, concentrates, crackers, etc.);

The “SANIN TRADE” company offers several kinds of BOPP films:

- Transparent BOPP. The excellent optical properties of this film include fine transparency, high lustre, low turbidity. Transparent polypropylene, with the thickness of 20 to 40 µm, is intended for packing confectionery, grocery, bakery and dairy products, as well as for production of film labels.

- Pearly-white BOPP is produced by partial efervescence/foaming of a film. Films, with the thickness of 30 to 40 µm, are intended for packing of confectionery, grocery and dairy products, as well as for production of film labels.

- Metallized BOPP are more economically than aluminum foil and has got a number of technological advantages, such as: reduction of the film mass weight, absence of damages of the metal layer when bending.

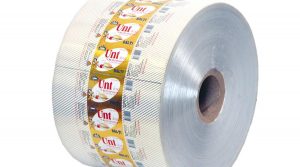

Laminated plastic on the basis of BOPP.

Laminated plastic on the basis of polypropylene contains a special heat-sealed layer that allows to make the packing of products with the help of termo-automatic machines with a wide interval of temperatures (from 115°C up to 150°С). The films can be used on the equipment for vertical packing, at seamwelding by means of hot air, elements of pulse or constant heating. Laminated plastic is widely used for packing of the frozen foodstuffs: bird’s meat, semifinished products, meat dumplings, vegetables and berries, pasta, household chemicals and other products.

the packing of products with the help of termo-automatic machines with a wide interval of temperatures (from 115°C up to 150°С). The films can be used on the equipment for vertical packing, at seamwelding by means of hot air, elements of pulse or constant heating. Laminated plastic is widely used for packing of the frozen foodstuffs: bird’s meat, semifinished products, meat dumplings, vegetables and berries, pasta, household chemicals and other products.

The SANIN TRADE company produces 2 types of laminated plastic:

BOPP + BOPP

BOPP + PE

Laminated plastic differs from single-layered materials, first of all, by the strength characteristics, and also by the improved appearance, basically – at the expense of shine and luster, which the external BOPP gives. The overprinting of laminated plastic differs, first of all, by its brightness, and also firmness to erasure, as external BOPP protects the print from erasure.

Characteristics of SANIN TRADE laminated plastic:

- high barrier permeability properties;

- frost resistance;

- additional protection of the print against mechanical damages;

- saturated color solution/decision;

- attractive marketable style;

- durability to punctures.

Technical characteristics:

- Width of linen/cloth: up to 600 mm

- Range of thickness: from 40 up to 75 µm

| External layer | Internal layer |

| Transparent BOPP Biaxially oriented polypropylene film |

Transparent BOPP Pearly BOPP Metallized BOPP Polyethylene |

By production of laminated plastic the external layer is overprinted in the mirror way.

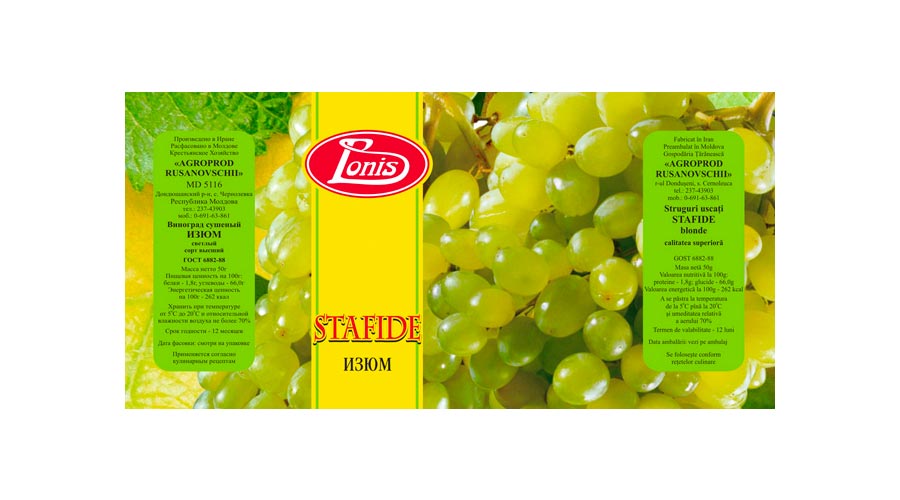

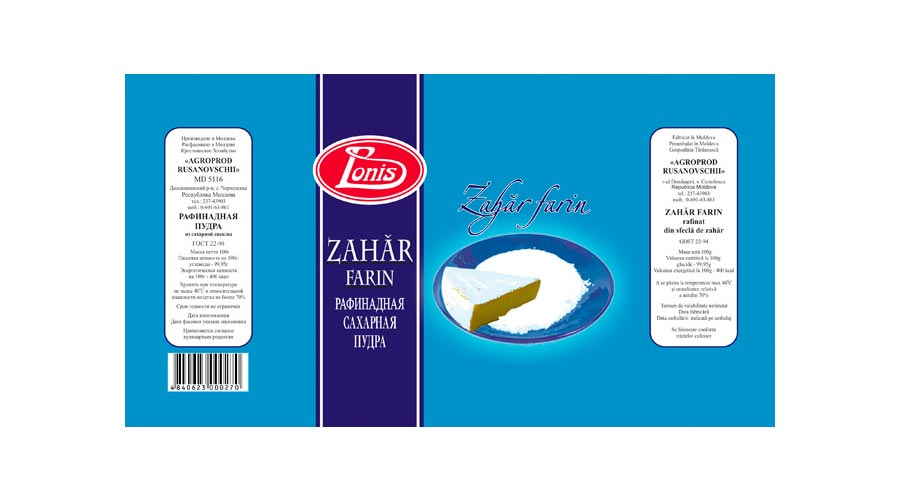

PET label

High-quality film label in combination with high-resolution multi-color printing gives the product an elite appearance, allows the effects of light and transparency in the design development.

As a material for film labels used polypropylene and pearl film. Undeniable advantages of film labels are durability and resistance to fading colors in the sunlight. The cost of each label is 40% lower compared to the paper, which will positively affect the cost of production. Application of film labels allows you to recycle pet without first removing. In the production of film labels used white-pearl, metallized or transparent polypropylene film, thickness from 30 to 40 microns.

Foil

The foil has a structure, which represents an ordered grid of metal atoms, which are located so densely that no gas, except hydrogen, can get through it. This foil property has defined its usage over years for packing of perishable goods (butter, margarine, curds, the glazed curd cakes, minced meat, etc.). An exclusive property of aluminum foil is its hygienic properties. The foil can be compatible with any foodstuffs, is thus absolutely nontoxic. It doesn’t confer to foodstuffs any foreign smell or taste, doesn’t let water and other liquids through, doesn’t absorb greasing substances. The foil used for flexible packing production represents a combined material, which consists of a foil (7-9 µm) glued with microwax or polyethylene and grease-resistant paper. The foil is perfectly suitable for packing of butter, margarine, yeast.

The foil can be compatible with any foodstuffs, is thus absolutely nontoxic. It doesn’t confer to foodstuffs any foreign smell or taste, doesn’t let water and other liquids through, doesn’t absorb greasing substances. The foil used for flexible packing production represents a combined material, which consists of a foil (7-9 µm) glued with microwax or polyethylene and grease-resistant paper. The foil is perfectly suitable for packing of butter, margarine, yeast.

- protection against light and a moisture;

- absence of influence on properties of products;

- maintenance of forms at packing;

- grease-resistance;

- bright, multicoloured print.

The laminated paper

consists of several components, that’s why it is possible to call it a combined material. The basic components of the laminated paper are: the basis paper and the polymeric layer which is applied onto it. Because of the properties inherent in paper and in polymeric layer, which are combined in the given combined material, laminated paper is a qualitative packing for a multitude of foodstuffs, light and pharmaceutical industry. With the help of flexoghraphic overprinting it is possible to use any kind of print.

consists of several components, that’s why it is possible to call it a combined material. The basic components of the laminated paper are: the basis paper and the polymeric layer which is applied onto it. Because of the properties inherent in paper and in polymeric layer, which are combined in the given combined material, laminated paper is a qualitative packing for a multitude of foodstuffs, light and pharmaceutical industry. With the help of flexoghraphic overprinting it is possible to use any kind of print.

Polyphane

The unique qualities of this environmentally friendly polyethylene film pushed her to the forefront in the international market of films with a twist effect. This material is designed specifically for the confectionery industry and consists of a polyethylene biaxial oriented film Polyphane. The effect of twist is achieved because the material of the base layer of the film is oriented in one direction and has a high residual deformation, ability to store twist when packing chocolates.

Polyphane is perfectly safe and environmentally friendly substitute for cellophane and polyethylene. This is possible due to the fact that he has an excellent ability to twist and high rigidity. Through a unique combination of thickness, specific gravity and chemical properties of polyphane, one unit weight of the material can be produced by tens of percent more sheets for candy, than from any other material. Polyphane neutral to sugar, chocolate, alcohol-containing fillers and other ingredients used in the manufacture of chocolates. To date, SANIN offers 4 types of films Polyphane: transparent, white, metallized and metallized with a white backing.

The advantages of this package:

ease of use

increase the shelf life of the product

high aesthetic appeal cost

the film with a twist-effect does not require energy for welding.

en

en  ro

ro ru

ru